System Overview:

The SE2000 platform has a comprehensive data acquisition and monitoring system (SCADA) function, energy management system (EMS) function, and wide area control system (WAMS) function, which can be widely used in various fields such as new energy generation, energy storage, power grid, electric vehicle charging and swapping, and multi energy complementarity.

The platform mainly consists of five parts:

The platform follows standards:

The SE2000 platform supports a wide range of international standards and protocols, including IEC60870-5-101, IEC60870-5-102, IEC60870-5-103, IEC60870-5-104, IEC61850, IEC61968/61970, IEC 61400-25, MODBUS, and Dnp3.0.

The SE2000 platform supports all mainstream operating systems, including Windows series, Linux, Unix, etc. The database supports Oracle, Sybase, DB2, SQLServer, MySQL, Dameng, Jincang, PI, etc. Supports bilingual Chinese and English interfaces.

The SE2000 platform adopts a modular structure, divided into dozens of modules according to their functions; The platform adopts a distributed architecture, and can be configured in any way according to user needs, such as single machine, dual machine, network, dual network, etc. The functional modules on each computer can be flexibly configured.

The platform has a distributed real-time memory database, a distributed coordinated operation mechanism, and distributed configuration and operation monitoring tools.

The SE2000 platform supports the deployment of Internet based cloud architecture, and can support large-scale real-time systems with more than one million sampling points. It can be widely used in new energy remote centralized control, large-scale energy storage station monitoring, online monitoring and asset management of power transformation and distribution equipment, centralized monitoring and operation and maintenance of substations, charging and replacement operation management, enterprise energy management and other fields.

The system has complete configuration software functions and can be flexibly configured using non programming methods, including configuration of the operating environment, network configuration, communication configuration, process configuration, database configuration, graphics configuration, report configuration, web configuration, etc. It supports scripting languages, C++API interfaces, web services interfaces, and user secondary development.

System Overview and Key Features:

System Overview and Key Features:

System Overview:

The Battery Energy Storage Power Station Online Analysis and Diagnosis Platform provides intelligent operation and maintenance management for energy storage stations. It performs intelligent maintenance, diagnostics, and safety warnings from the energy storage station level down to the stack, cluster, and individual unit levels. At the same time, it conducts intelligent monitoring of BMS, PCS, high-voltage switchgear, fire protection equipment, and other electrical devices. The platform offers battery preventive diagnostic technical services based on cloud platforms and artificial intelligence algorithms, targeting the cell level. It realizes local and online data analysis and processing, predicting fault locations and causes in advance, and visualizing diagnostic information results. Additionally, it provides supporting software and hardware for data collection and forwarding, edge computing, and cloud platform preventive diagnostic functions, offering a full lifecycle intelligent management solution for the safe monitoring and management of energy storage stations. By dynamically adjusting charging and discharging parameters based on battery status, it extends battery life and improves system safety, reliability, and cost-effectiveness.

The intelligent operation and inspection platform for energy storage stations is an advanced system that goes beyond traditional data management and status monitoring. It is capable of real-time evaluation of the status of massive devices such as lithium-ion batteries. It provides multi-dimensional and multi-index evaluations of operational status, including consistency evaluation, health status evaluation, and other services. The platform can precisely locate fault points or potential fault points in each battery module and battery cluster. By integrating workflow, GIS, and IoT technologies, it achieves task assignment, precise location, and timely elimination of operational risks.

System key Functions:

System Overview and Key Features:

The industrial and commercial energy storage EMS system achieves the balance and optimization of electricity demand for industrial and commercial users in terms of power grid, new energy, batteries, and loads, bringing application value in peak and valley electricity consumption, distribution network capacity expansion, electricity safety, and other aspects.

Real time monitoring of power grid load situation, intelligent scheduling of energy supply and storage demand based on electricity demand and energy storage status, charging during low valley electricity prices and discharging during peak electricity prices, achieving peak load transfer and obtaining profits from peak valley electricity prices.

Combining multiple energy sources and loads in microgrids, such as power generation networks, motors, photovoltaics, loads, charging, etc., to achieve complementary and collaborative work among sources, networks, loads, storage, and charging can improve the utilization of renewable energy and the quality of electricity.

When the power grid fails or experiences a power outage, the energy storage system can quickly respond, provide backup power, and ensure the power supply of critical equipment.

Energy storage systems can reduce maximum demand. EMS tracks load power to ensure that there is no increase in demand due to charging; When the actual load increases, causing an increase in demand for this month, the energy storage battery begins to discharge, reducing the demand for distribution power, thereby reducing the maximum demand and lowering electricity costs.

In response to electricity demand, industrial and commercial users actively reduce electricity consumption (energy storage and discharge) when electricity is scarce, respond to power supply balance through peak shaving and other methods, and obtain economic compensation as a result.

The energy storage system detects the power of the grid connection point, controls the energy storage output, and ensures that battery discharge does not cause reverse power transmission.

System Overview and Key Features:

Communicate with all devices to form a source grid load storage microgrid and connect data silos. Based on multi energy collaboration technology, unified management of various power generation and consumption equipment is achieved to achieve precise control of energy consumption in the park and accurately grasp the power generation and consumption situation in the park.

All collected data can be displayed on the screen, such as power station information, system status, SOC, etc. Data analysis can also be conducted.

Support multiple control strategies, including anti backflow strategy, demand electricity price control, coordinated operation control strategy, peak valley time of use electricity price mode, to meet various usage scenarios in industry and commerce.

Cloud edge collaboration. The combination of remote centralized control and local control, coordinated operation of cloud, edge, and end, allows for both remote issuance of control instructions and on-site operation and maintenance personnel to complete the issuance of operation instructions.

System Overview:

The system collaborates with thermal power units to carry out grid AGC frequency regulation business. When the system is frequency regulated, it outputs 9MW/2C, and the AGC adjustment is fast and accurate. The system operates stably, which can greatly improve the AGC frequency regulation level of thermal power plant generators. The power plant can obtain profits by charging electricity fees to the energy storage system and sharing AGC compensation.

FM control process:

System Overview:

The data acquisition device supports communication with multiple on-site hardware devices via TCP or 485/232 interfaces. It supports various communication protocols such as MODBUS/MODBUS-TCP, IEC104, IEC61850 MMS, IEC61850 Goose, MQTT, etc. It features a short debugging cycle, good system compatibility, flexible deployment, and other characteristics. The device offers flexible client configuration, true client maintenance-free operation, and remote maintenance.

System Key Functions:

System Overview:

The virtual power plant system supports the access of distributed energy devices based on the characteristics of virtual power plants. By connecting multiple types of energy devices, these devices are aggregated together as a whole and participate in various demand adjustments in the auxiliary service market as a third-party auxiliary subject.

Unlike the monitoring of conventional power plants, this system monitors the operation of distributed photovoltaic, energy storage, adjustable load, interruptible load and other resources from the perspective of virtual power plants, focusing on monitoring the overall characteristics of distributed energy to the outside world. The detailed wiring and operation mode of distributed energy can be monitored according to actual needs.

Application scenarios:

System Overview:

By adopting technologies such as intelligent perception, industrial Internet of Things, and data conversion, the mining power supply data is standardized, and a series of functions such as intelligent display, query, alarm, remote control and automation operation, fault location and analysis are realized. This platform supports full data interconnection and full process integration and sharing, providing strong support for the intelligent management of coal mine power supply systems.

System key Function:

Communication Management Machine Overview:

The communication management machine is mainly deployed in industrial sites and has functions such as centralized data collection, communication protocol conversion, and multi-directional data forwarding. It can be widely used in energy monitoring and management fields such as power grid transmission and distribution, wind power, photovoltaic, solar thermal, energy storage, electric vehicle charging and swapping, hydropower, and thermal power. The communication management machine is connected downwards to data acquisition devices, measurement and control instruments, SCADA systems, DCS systems, etc., to collect data; Integrate with the main station system, cloud platform, etc. upwards, and send the collected data.

Communication Management Machine Key Features:

System Overview and Key Features::

A photovoltaic power station consists of independent subsystems such as a photovoltaic power generation system, a substation system, a distribution system, a security monitoring system, a dispatch remote control system, an AGC/AVC control system, an optical power prediction system, an environmental monitoring system, and a power quality monitoring system.

The comprehensive monitoring system of Delian Photovoltaic Power Station can integrate the above independent systems, providing real-time data acquisition, data processing, data transmission, data storage, operation monitoring, operation control, alarm processing, statistical analysis and other functions. Can build a comprehensive data platform for photovoltaic power plants based on full data, providing panoramic display function and a unique human-machine interaction interface for dispatch and operation personnel.

The communication between the monitoring system and various subsystems in the station is modularized, supporting common protocols in the power industry such as Modbus RTU/TCP, IEC 101, IEC 102, IEC 103, IEC 104, CDT, etc. Non-standard communication protocols can be implemented by adding communication modules.

The monitoring system adopts cross-platform technology, supports Linux and Windows operating systems, and supports multiple SQL databases such as SQL Server, Oracle, MySQL, etc. Adopting real-time in-memory database technology greatly improves the efficiency of real-time data processing. The system's human-machine interface and reports use configurable technology, with a rich chart library, allowing users to customize graphic elements and templates. Simple, standardized, and user-friendly monitoring screen design provides a relaxed and easy work experience for on-duty personnel in the monitoring center.

System Overview and Key Features:

System key Functions:

System Key Features:

System Key Functions:

System Key Functions:

Implement centralized management of charging equipment and monitoring information, establish an integrated system for basic information and operational data application services, and provide comprehensive information resource services for various government departments, vehicle owners, new energy vehicles, and energy vehicle manufacturers.

System Key Elements:

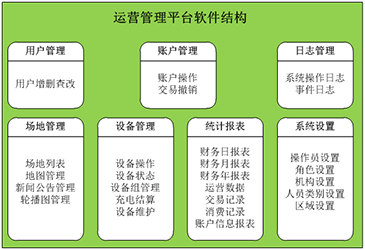

Software structure of operation management platform:

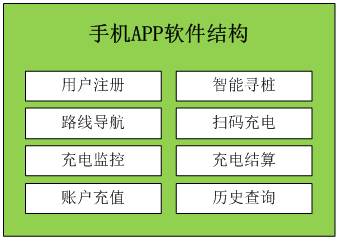

Software structure of mobile app:

System Overview:

The Wind Power Centralized Control Platform integrates the monitoring systems of different equipment manufacturers within the wind farm, builds a unified data monitoring and control platform, and constructs a unified massive real-time wind turbine data monitoring platform. It centrally monitors and controls the information of different types of wind turbines in the wind farm across manufacturers to achieve functions such as data collection, equipment control, measurement, parameter adjustment, accident alarm, prediction, etc. It also provides data interface support for coordinated operation with the higher-level control center, greatly reducing on-site duty personnel and improving the level of intensive management.

System architecture:

Establish a wind power monitoring and management center at the company headquarters, and set up regional control centers in provinces where wind power is concentrated. The regional control centers manage various wind farms within their jurisdiction. The system adopts a four layer architecture, which is divided into acquisition layer, field control layer, centralized control layer, and overall control layer.

The collection layer is located inside the wind turbine tower and mainly includes the wind turbine control PLC and various sensors, which are used to collect data and status of the unit. Through calculation, analysis, and judgment, it controls a series of control and protection actions such as starting, stopping, adjusting direction, braking, and opening the oil pump of the unit. It can enable a single wind turbine generator unit to achieve full automatic control without human intervention. The equipment layer has the ability to independently handle wind turbine failures under various abnormal operating conditions, ensuring the safe and stable operation of wind turbines.

Communicate with the equipment layer downwards to collect wind turbine operation information, booster station operation information, power prediction information, other equipment information, etc., and communicate with the centralized control layer upwards to send real-time aggregated information of the entire wind farm to the centralized control layer.

The centralized control layer is located in the regional control center, communicating downwards with the field control layer to collect operational information of various wind farms in the area. At the same time, it can directly issue various control and adjustment commands to the field control layer. After receiving the commands, the field control layer will then issue them to specific equipment (wind turbines, booster stations, etc.); The centralized control layer communicates with the overall control layer and sends real-time information about important wind farms in the area to the overall control layer. The centralized control layer has the function of centralized monitoring and control of all wind power generation equipment in this area.

The overall control layer is the control and dispatch center for all wind farms scattered throughout the country for the company.

Communicate with the control layer, receive operational information from wind farms in various regional centers, and send various control, regulation, data call, and other commands to the control layer. The overall control layer gathers the main information of all wind farms in the country.

The control layer has the function of analyzing and mining massive real-time and historical data, which can optimize and schedule the operation of wind farms from a global perspective, and provide guiding suggestions for the intensive management of wind power generation. To solve the problems of on-site operation and maintenance of wind farms and personnel management, the company's centralized management and centralized dispatching can be realized by changing the decentralized operation and management mode of wind power, realizing unattended and less on duty wind farms, reducing the operation and maintenance costs, and achieving the goal of reducing personnel and increasing efficiency.

System Key Functions:

System Overview:

The Control and Management Platform for HVAC System consists of an energy monitoring platform, data analysis model, energy-saving operation instructions, and equipment inspection center. It is the center for information collection, energy efficiency analysis and processing, energy-saving operation instructions, and equipment alarm transmission of the entire building's energy.

System Key Functions:

Data collection function, monitoring function, basic energy management function, energy consumption prediction function, equipment failure and energy consumption alarm function, operation system management function, etc. It combines the Internet of Things, big data, and energy management to intelligently control and assist in efficient energy utilization, providing a safe, comfortable, and energy-saving environment.

Background Overview:

With the continuous improvement of power automation level, improving production efficiency and ensuring safety production are practical problems currently faced by enterprises.

The setting of the power dispatching system enables the work done by the on duty personnel in the original substation to be completed remotely, achieving the goal of centralized control, unified scheduling, unified maintenance, and unified inspection, and realizing unmanned or few person on duty in the substation.

System Overview:

The Electric Power Dispatching System adopts a distributed structure based on redundant dual networks, and the hardware and software support platforms follow international open standards and specifications while complying with distributed requirements. The application development is based on an object-oriented application development system, and the support platforms for various applications such as SCADA should be designed in an integrated manner. Supports Windows and Linux operating systems, with the ability to switch between Chinese and English to meet the needs of users in different regions.

The system automatically switches functions between redundant hardware devices through mechanisms such as the CEO election protocol, ensuring the availability of the entire system functionality is not affected by individual device failures. The historical data server, SCADA server, data acquisition server, front-end server power supply, etc. of the system are all configured redundantly. When one fails, its functions are automatically replaced by its backup equipment to ensure the normal operation of the system.

System Key Functions:

Electric energy metering and billing system:

System Background:

In recent years, the operation and maintenance of transformer (distribution) power stations has become an industry trend, and many power installation and maintenance companies in various regions have transformed into transformer (distribution) power station operation and maintenance companies. For these hosting and operation companies, the traditional reliance on manual duty is not only inefficient but also costly, and can no longer meet the needs of industry development. How to reduce staff and increase efficiency? Internet plus is the only way.

Deloitte has developed a centralized monitoring and management system for power transformation (distribution) (hereinafter referred to as the centralized control system) by deeply integrating mature power automation technology with the latest Internet and Internet of Things technology. The centralized control system has complete data collection and monitoring functions, and can fully display the real-time operating conditions of the power grid in the form of graphics, reports, etc. When a power grid accident occurs, the system can automatically sound an alarm, reminding dispatch and operation personnel to handle it in a timely manner, and can send the alarm information to relevant personnel through SMS, WeChat, and other means. The collected power grid operation data can be automatically stored for several years. The system has big data analysis capabilities and can submit power equipment condition reports and energy consumption analysis reports to users based on historical data, providing guidance for operation, maintenance, and energy conservation and emission reduction.

With the help of this centralized control system, the entrusted operation and maintenance company can achieve unmanned operation, centralized monitoring, and on-demand scheduling of maintenance personnel for transformer (distribution) power stations, reducing operation and maintenance costs, improving operation and maintenance efficiency, and increasing user satisfaction.

System Key Functions:

System Key Features:

System Overview:

The Delian Photovoltaic Centralized Control Operation and Maintenance Cloud Platform is a software service platform built based on advanced technologies such as the Internet of Things, cloud computing, big data, and AI to serve distributed photovoltaic power plants. It solves the problems of scattered sites, difficulties in operation and maintenance, and high operation and maintenance costs in distributed photovoltaic power plants. It can extend the lifecycle of photovoltaic power plants and improve power generation efficiency. The Delian Photovoltaic Centralized Control Operation and Maintenance Cloud Platform can connect to both large and medium-sized centralized photovoltaic power stations, as well as small distributed photovoltaic power stations.

System Key Features:

Scope of application:

The energy metering and billing system can be applied to various users such as power plants, substations, large users, residential areas, regional power grids, and electricity sales companies.

Electric energy data collection:

Electricity statistics and calculation:

Electric energy metering and billing system:

System Overview:

The software functions of the Baoxin sub-station platform include calling and querying protection parameters and values, switching between fixed value area codes, transmitting fixed values, real-time monitoring of analog, status, and electrical measurement data, monitoring the communication status of devices, downloading waveform files, and displaying waveform curves.

This platform can be divided into the following functional modules:

The main features of the platform are as follows:

System Overview:

This platform integrates functions such as fault recording query, fault remote signal monitoring, system event recording, device setting, manual recording, and waveform curve display, making it easy for users to quickly, efficiently, and correctly analyze grounding faults.

This platform can be divided into the following functional modules:

The main features of the platform are as follows:

System Overview:

This system is a remote safety information monitoring and management product for elevators based on Internet of Things technology. By collecting the operation status, faults, and maintenance status of the elevator through independent sensors, and uploading them in real-time to the elevator operation management platform via wireless/broadband networks, the elevator can achieve all-weather operation monitoring, fault information recording, active alarm and maintenance management.

System Key Features:

System Usage Benefits:

System Overview:

The functions of the new energy evaluation system include two aspects: intelligent evaluation analysis and data mining analysis.

Intelligent Evaluation Analysis:

Data Mining Analysis:

System Overview:

The Delian Intelligent Operation Ticket System employs network topology and operation simulation technology to create a network model of the actual power system. By integrating graphics and ticket technologies, it offers practical features such as intelligent generation, automatic simulation, automatic topology coloring, automatic safety verification, and comprehensive process management of operation tickets.

System key Features:

Key Advantages of 3D and VR Technology:

3D animation and virtual reality (VR) offer remarkably realistic simulations of the real world. From the intricate details of the micro world to the vast expanse of the macro world, both tangible spaces and imaginative realms are brilliantly portrayed.

System Overview:

This system effortlessly creates 3D real scenes across sectors such as power transmission, distribution networks, wind energy, solar power, storage solutions, and electric vehicles. It correlates these 3D models with the grid's real-time operational status, visualizing data shifts through diverse indicators like lights and numerals. Upon meeting predefined criteria, it issues alarms by altering the 3D model's color, shape, or position, among other visual cues.

The system offers two browsing modes: automatic inspection and manual scene exploration, controllable via keyboard and mouse.

System key Features:

| C/S mode |  |

Develop various power system related software based on Windows or Linux operating systems, using QT or VC++. |

| B/S mode |  |

Develop various real-time web publishing and management software based on TOMCAT, JAVA, JS, SSH and other technologies. |

| APP mode |  |

Develop various mobile terminal APP software based on Android and iOS. |